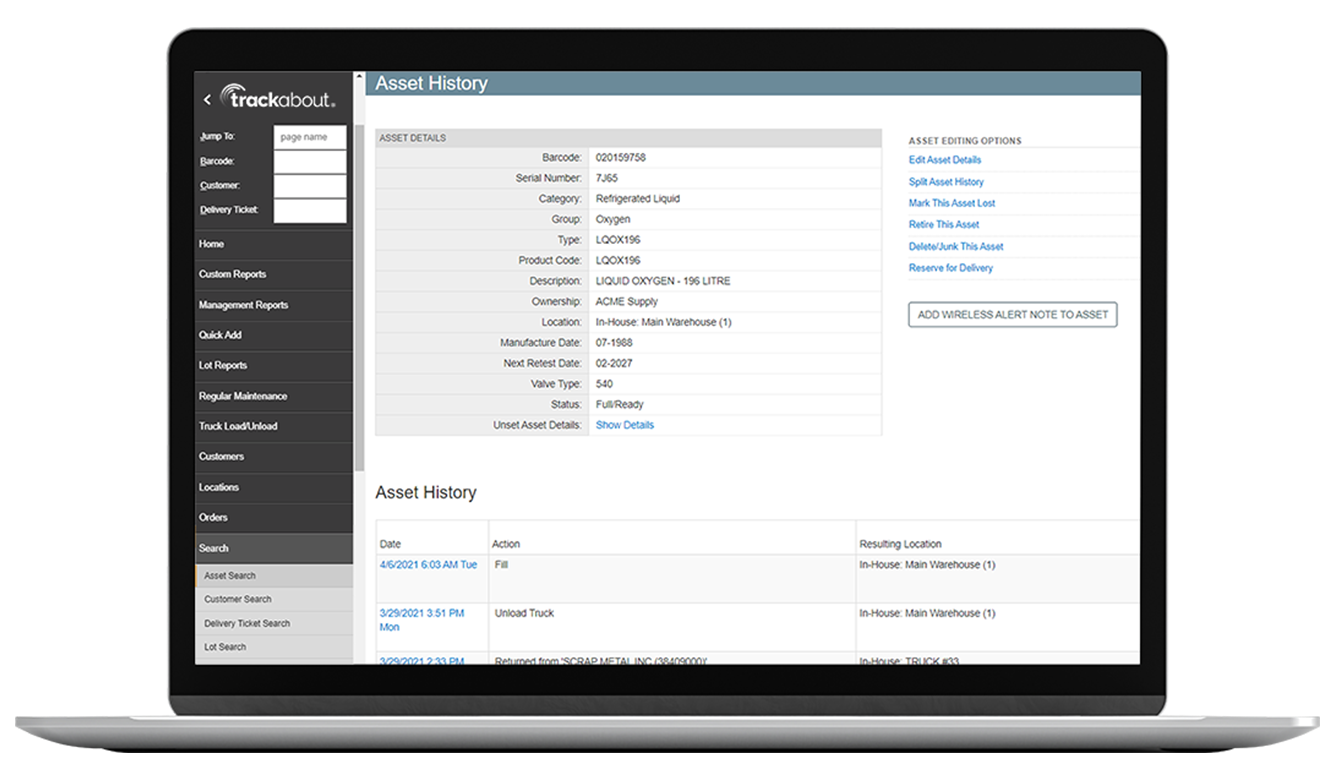

The hub of your TrackAbout solution, TrackAbout Web is where our experts will set up and maintain your tracking program and where business managers will come to better understand your returnable container processes. Any and all changes can be made through the TrackAbout Web interface, from adjusting workflows to adding new vendors for rental equipment. User permissions can also be established to configure screen views and options for specific roles and promote data security.

.png)