Contact Sales |

+1 800.960.1510 |

Linweld, Inc. is one of the country’s leading manufacturers and distributors of medical, specialty and industrial gases and welding supplies.

The University of Kansas (KU) requested Linweld’s help with improving the efficiency of its internal gas cylinder tracking system. KU used a time-consuming manual process that required people to write down cylinder types and tracking numbers for deliveries and returns. This information was then keyed into a homegrown database program. Errors were frequent, and cylinders delivered to one department often were returned from another, resulting in incorrect rental charges. “Cylinder audits were a nightmare. It took us four days to track down our 600 tanks in all the different buildings,” said Susan Teague, KU’s chemistry department business manager.

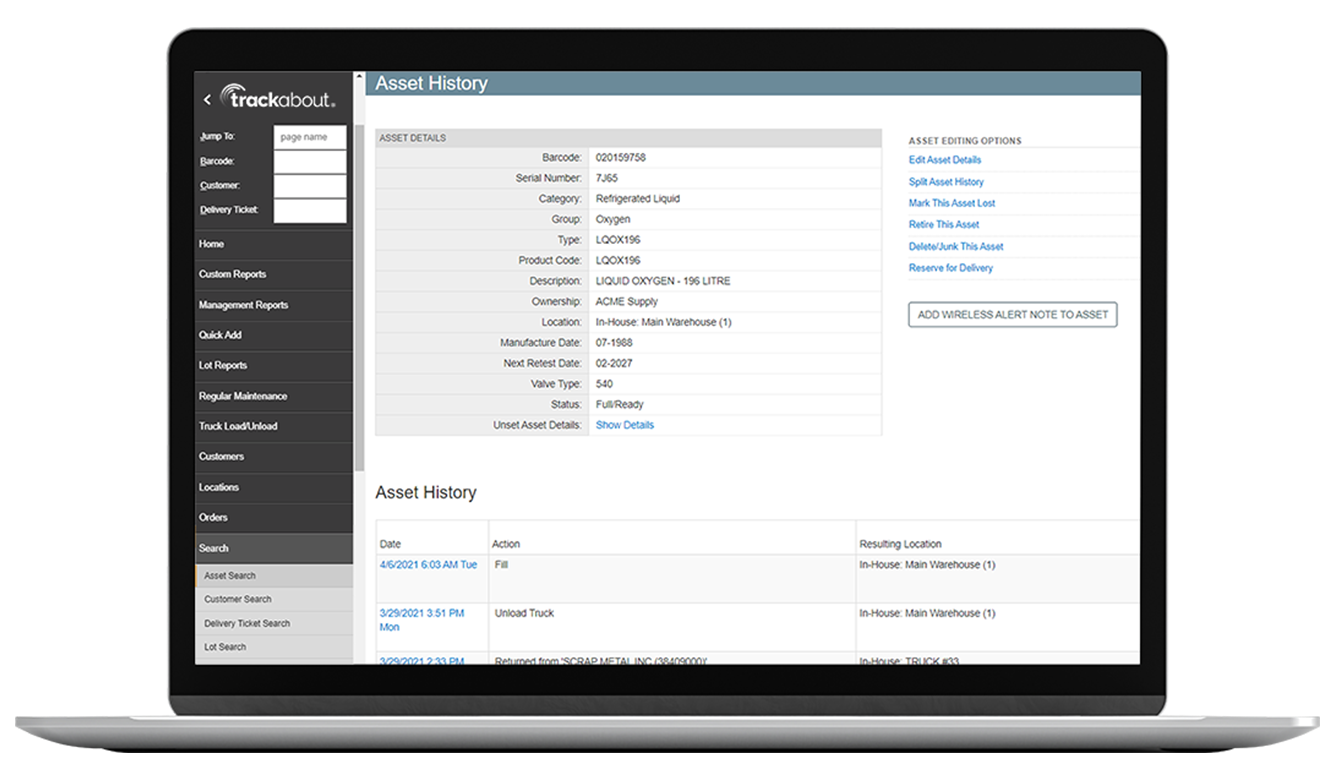

Linweld implemented TrackAbout's TrackAbout module to help KU automate its gas cylinder tracking process. Now handheld scanners are used to scan cylinders upon delivery, checkout and return, ensuring that rental fees are charged correctly. Scanners have expedited the audit process significantly. Both KU and Linweld have immediate access to the same data on the TrackAbout system, giving them a single view of the truth and making it easy to resolve discrepancies. Clearly visible audit trails eliminate confusion about usage and balances and enable users to track cylinder location, movement and physical characteristics such as contents, age and lot number. Linweld can check the number of empties waiting for pickup at any time. Electronic alerts can notify users of impending expiration dates, days held, delivery of hazardous materials , and other asset conditions.

Follow-On Tracking has given KU a high degree of control and visibility so it can effectively monitor and manage all cylinder movement. “We used to spend two hours a day updating our homegrown tracking system,” said Teague. “Now that’s down to just twenty minutes.” Audits take two days instead of four and accuracy has greatly improved. “With TrackAbout there’s less room for human error so we get the information right the first time,” Teague noted.

Other Linweld customers using the cylinder tracking solution have benefited as well. “Follow-On Tracking eliminates manual paperwork, takes less time and is considerably more accurate,” said Greg Vasek, president of Linweld. “Clients can view their own asset information online, which helps eliminate balance and billing disputes, enhances trust and accountability and enables us to create stronger partnerships with our customers.”

Discover how our software can help you achieve greater container visibility and utilization. Schedule a free consultation with TrackAbout today.

322 North Shore Dr.

Building 1B, Suite 200

Pittsburgh, PA 15212

© 2025 TrackAbout | All Rights Reserved | TERMS OF SERVICE | PRIVACY POLICY | RESPONSIBLE DISCLOSURE