Contact Sales |

+1 800.960.1510 |

KC Bier Co. is a popular regional brewery based out of Kansas City, Missouri. The business opened in 2014 wanting to bring authentic-tasting German ales and lagers to the masses.

authentic-tasting German ales and lagers to the masses.

KC Bier employs about 50 staff – all committed to sharing their passion for traditional locally-brewed beers that are unfiltered, unpasteurized, and as natural as possible.

Using traditional brewing techniques, KC Bier specializes in Bavarian-style beers lovingly crafted using the finest malt, hops, and yeast imported from Germany. It produces and distributes these from its Kansas City headquarters, a facility that has grown with the business over the years and now includes its own Bierhalle where locals can experience its range of beers alongside pretzels, German sausages, and other favorite bar snacks.

Over the past decade, Kansas Citians have gotten a taste for KC Bier’s unique offering, with the brewery now selling in excess of 14,000 barrels of beer annually.

Unlike most breweries of its size, KC Bier owns its kegs rather than renting them. The business had always replenished its keg stocks on an ad-hoc basis, but found it was getting increasingly difficult to keep track of them all and know exactly how many were available and useable.

Used kegs were often going astray – either being discarded or kept by customers, while it also proved tricky to monitor, maintain, and repair those that were returned.

“We had been growing and growing, buying kegs whenever we didn't have any on hand – and not thinking too hard about where they all went or how many were coming back,” says Josiah Helber, KC Bier’s Operations Manager. “When I started taking a closer look and going through our stocks, I realized our distributors held more outstanding keg deposits than we had purchase receipts for kegs. We decided we needed to get to grips with the problem.”

With kegs costing anywhere from $85 to $120 each, the business was keen to make better use of these valuable assets and cut unnecessary expenditure.

“We weren't doing a good job of keeping track and we didn't have good data,” he says. “We would just keep buying more whenever we would start running low. Eventually, we decided we needed to know who had how many, how long they'd been there, and which ones weren't coming back.”

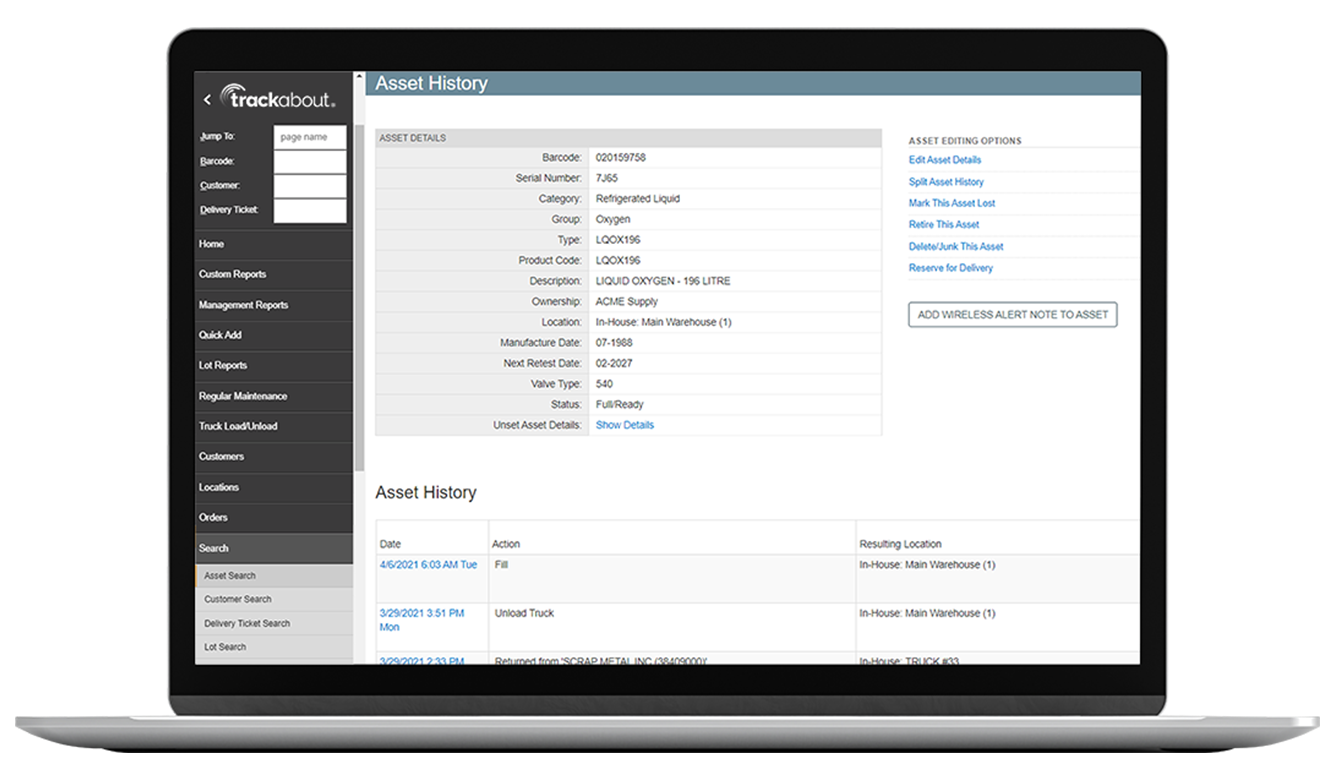

In 2019, KC Bier decided TrackAbout’s market-leading asset management software would be the perfect solution. By being able to better track keg cycling and carry out preventative maintenance, KC Bier was also able to maximize the use of it assets and significantly cut costs.

The business carried out a thorough audit with its distributors as a starting point, asking them to provide a count of all the kegs they had in the warehouse and out in the retail environment. Then with the support of TrackAbout’s Implementation team, all the details about these assets was added to the system.

Now, each time a keg is filled, shipped, or received, a label on the keg is scanned and the software instantly captures information about its status, contents, customer, and condition.

“We have a lot of money invested in our kegs and there are all kinds of tax and accounting implications of knowing how we’re using our equipment. It doesn't necessarily streamline processes or make the job of the operators easier – after all, it is something extra for them to do – but it's a layer of insurance that tells us everything's okay.”

The onboarding process was simple, says Helber, with KC Bier’s team trained to use TrackAbout’s dedicated mobile app on their cell phones, properly affix the high-quality durable Metalcraft stickers that had been recommended, and understand what they needed to do to add assets to the system and collect the required data.

“The entire process was relatively straightforward,” adds Helber. “Our TrackAbout representative helped me get everything up and running. There were no real stumbling blocks.”

KC Bier is now able to quickly collect information, including attributes such as the type of barrel, item numbers for the different kinds of beer and kegs, their status – empty versus full, and lot numbers. It was even able to stipulate which information was mandatory, so employees couldn't advance without capturing the correct details.

“I think we’ve purchased just over 8,000 kegs in the life of the company – but since we've been using TrackAbout we've scanned 7,900, so we haven't lost many,” he says.

The business eventually plans to use TrackAbout’s software to monitor the maintenance and servicing of the kegs to ensure those approaching the end of service life are replaced or repaired. It is also considering purchasing returnable plastic pallets, adding these to the system, and tracking these as well, he says.

“TrackAbout is the simplest, most straightforward way to do this kind of tracking,” says Helber. “It’s absolutely worth it when you’ve got assets that are worth a lot of money, have deposits involved, and where there are tax implications to knowing how many of these exist. Software like this is essential.”

Discover how our software can help you achieve greater container visibility and utilization. Schedule a free consultation with TrackAbout today.

322 North Shore Dr.

Building 1B, Suite 200

Pittsburgh, PA 15212

© 2025 TrackAbout | All Rights Reserved | TERMS OF SERVICE | PRIVACY POLICY | RESPONSIBLE DISCLOSURE